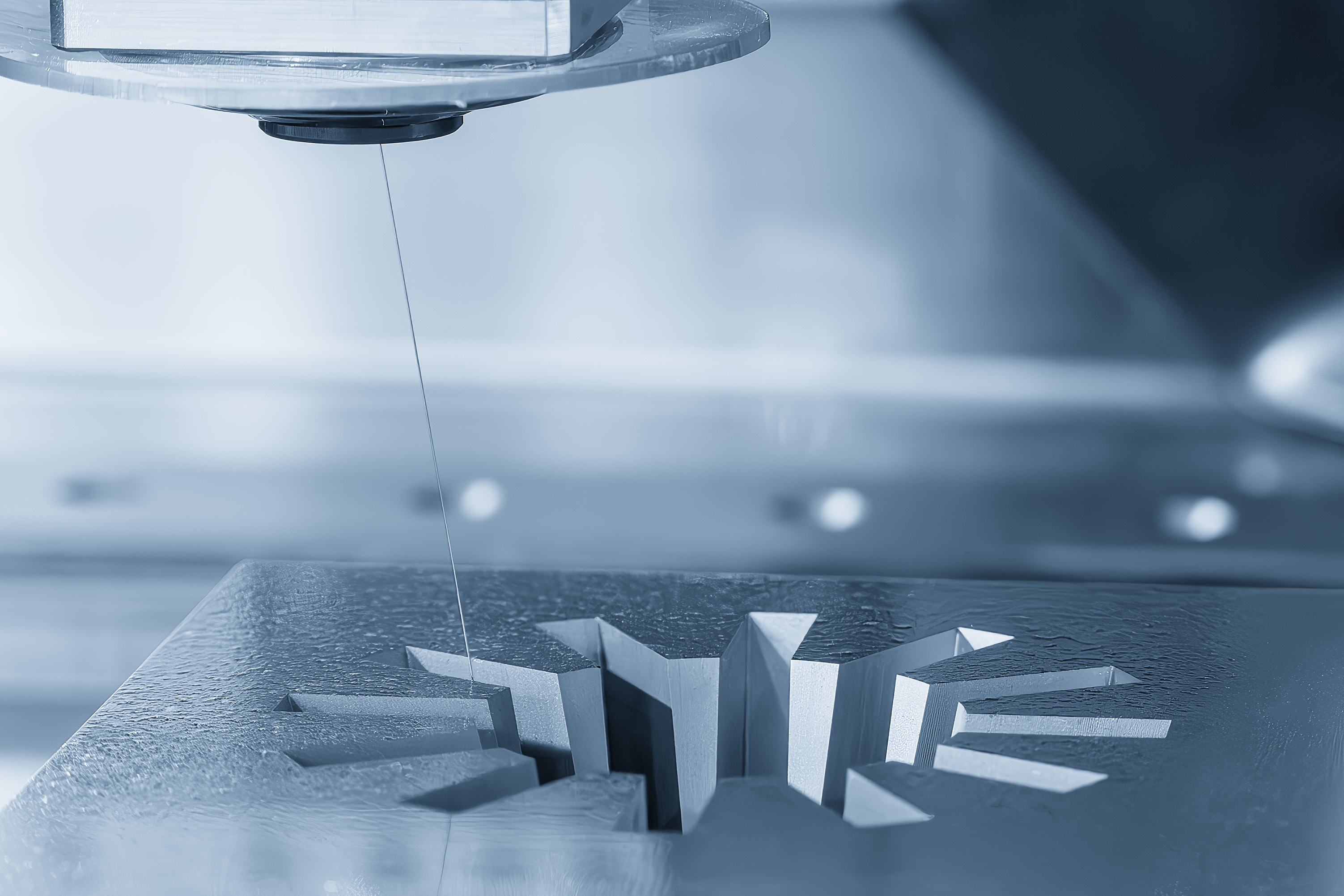

Wire EDM Machining

Aligned for Precision and Speed

Our shop's world-class wire EDM equipment delivers better lead times without sacrificing precision or quality when cutting complex shapes or hard materials.

Conventional EDM Capabilities

Quality Results with Wire EDM

Our wire-cut EDM machines produce intricate molds, dies, and cavities with exceptional detail. The EDM process minimizes deformation and maintains thermal stability for superior results when machining hard-to-cut materials.

Large-Format EDM Capabilities

Size and Weight Meet Precision

We process oversized and heavy workpieces with precision and efficiency using our Charmilles 640CC and extended-tank 440 wire-cut EDM machines.

-

Dimensions: Up to 1300mm x 1000mm x 510mm

-

Machining travels: Up to 800mm x 550mm x 510mm

-

Submerged cutting depths: Up to 510mm

-

Bar-type material: Up to 1500mm with full-length machining

-

Workpiece weights: Up to 3000kg

-

Unattended cycles: Over 40 hours with extra-large wire spool handling capabilities

Wire EDM Spinning Capabilities

Achieve Fine Features with Tool-Free Machining

We use EDM spinning to deliver fine features without the tool pressure of other CNC processes for high-precision micro applications like electrical probes and semiconductor spot-welding electrodes.

EDM Drilling Capabilities

Overcoming Complex Challenges for High-Risk Industries

Capable of drilling extremely small and deep holes, our spark-cut EDM equipment excels in machining complex geometries and hard materials like titanium and tungsten for medical, electronics, defense, and other industry applications.

Certifications

It's not just a process and a certificate to hang on the wall. It's who we are. Our commitment to quality and security is the only way.

Contact Us

Working With Us

Learn how we support customers from day one, from machining to automation, engineering, and more.

Contact Us