See Us In Action

PMi2 incorporates and designs automation and robotics station.

Overview of the various CNC equipment at the PMi2 in Westminster, South Carolina.

PMi2 headquarters is located Westminster, South Carolina, close to major OEMs and suppliers.

A view down the center aisle of PMi2’s Westminster, South Carolina facility.

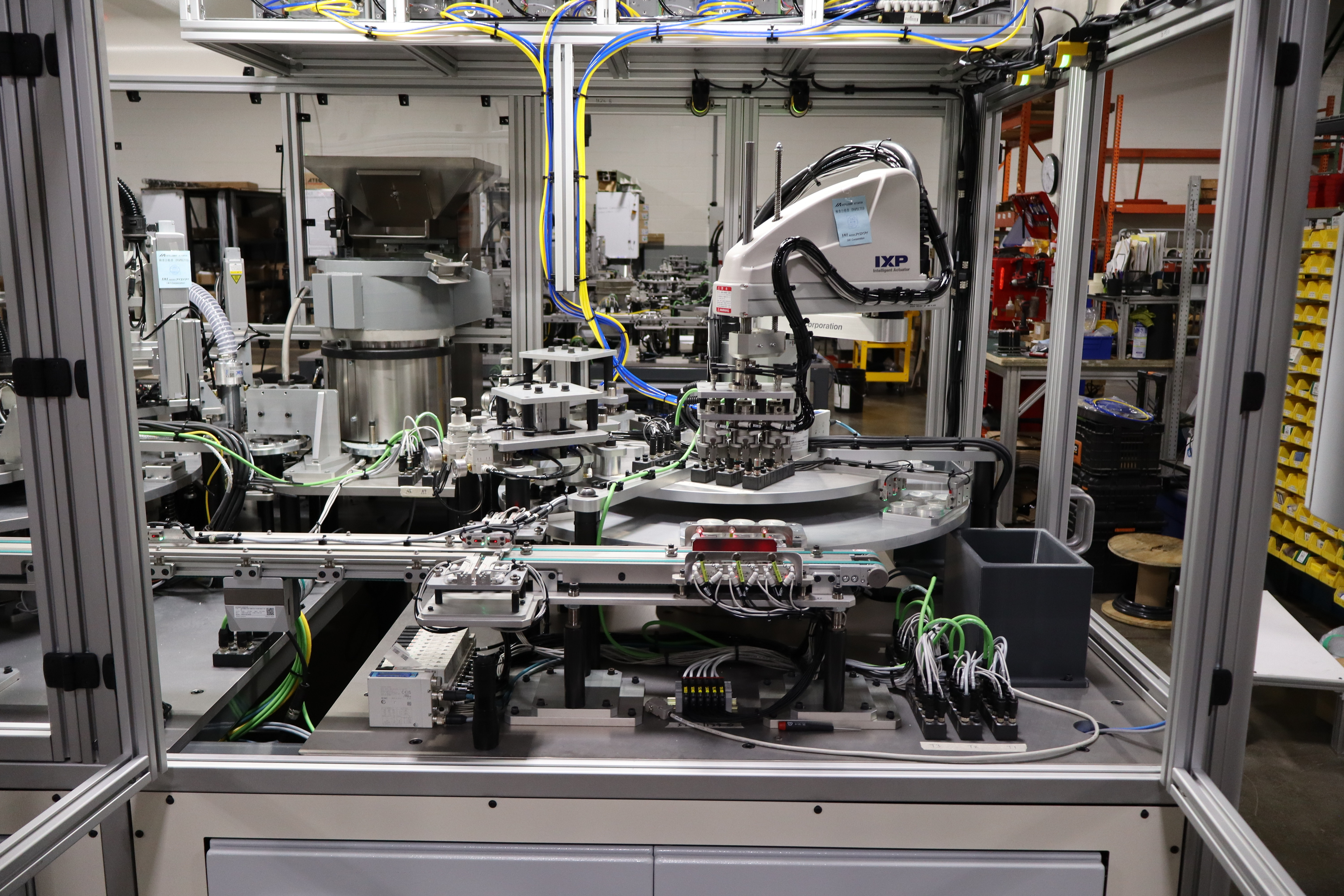

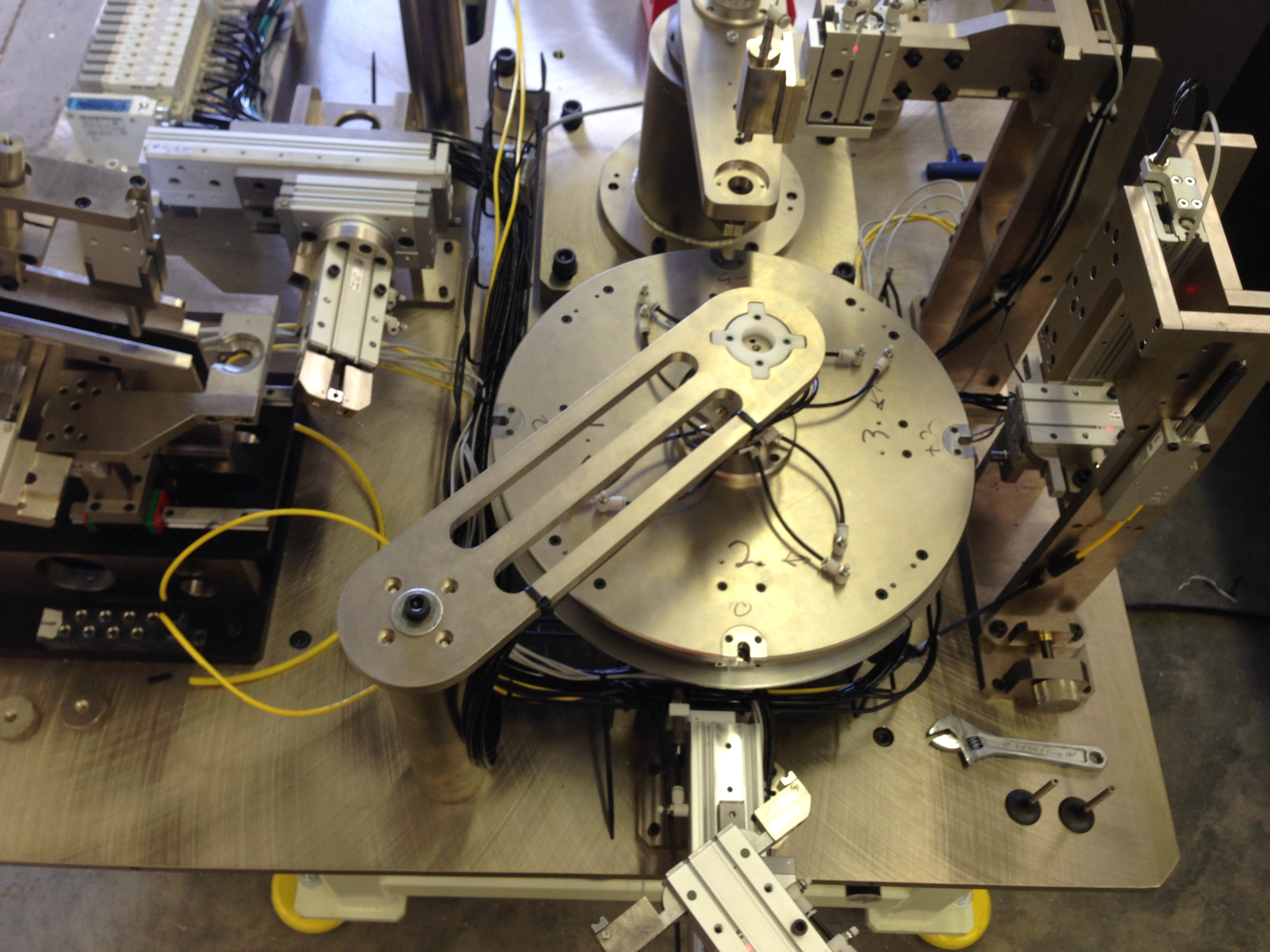

PMi2 designed and built an IXP machining table using Intelligent Actuator equipment.

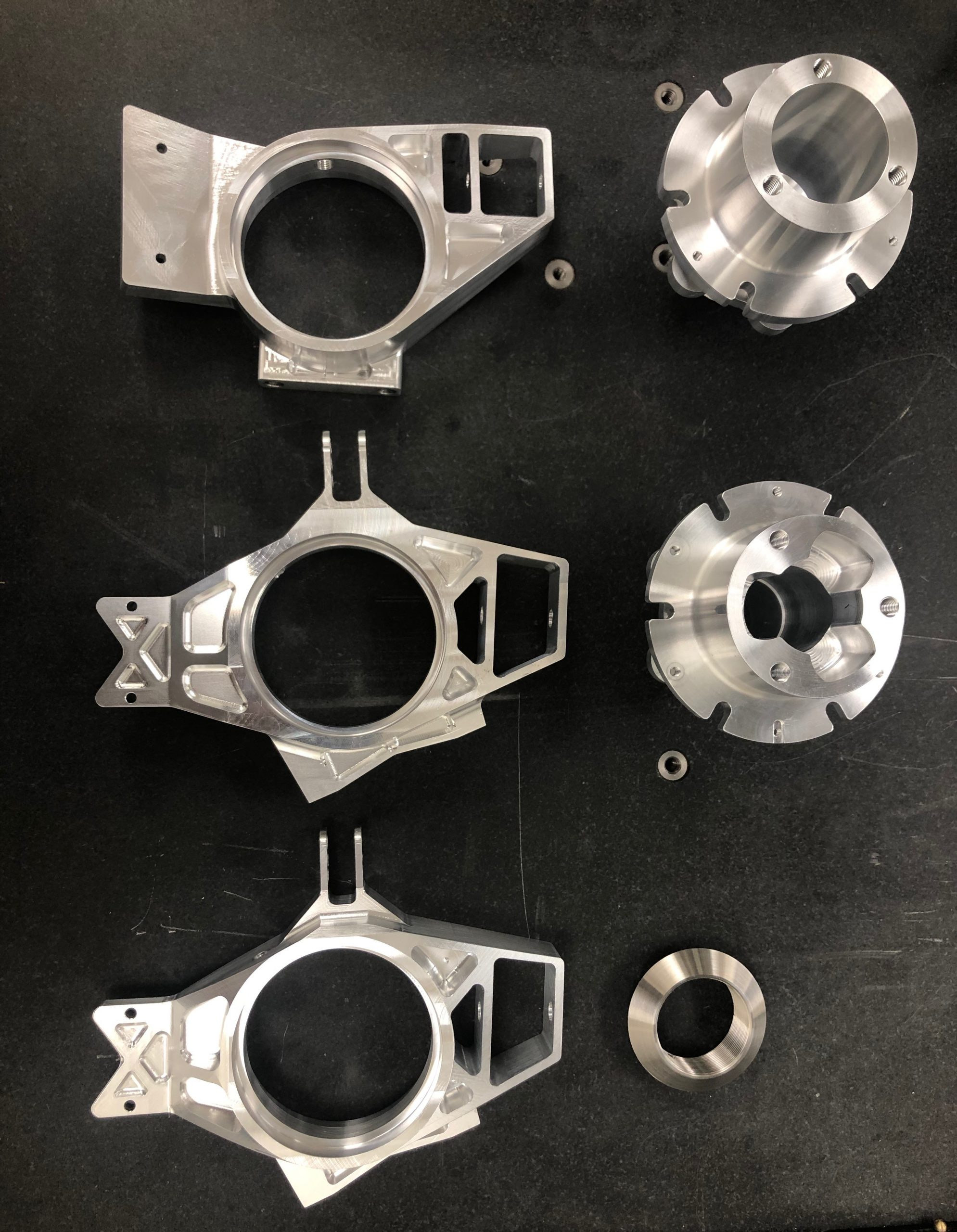

A collection of freshly machined parts from PMi2.

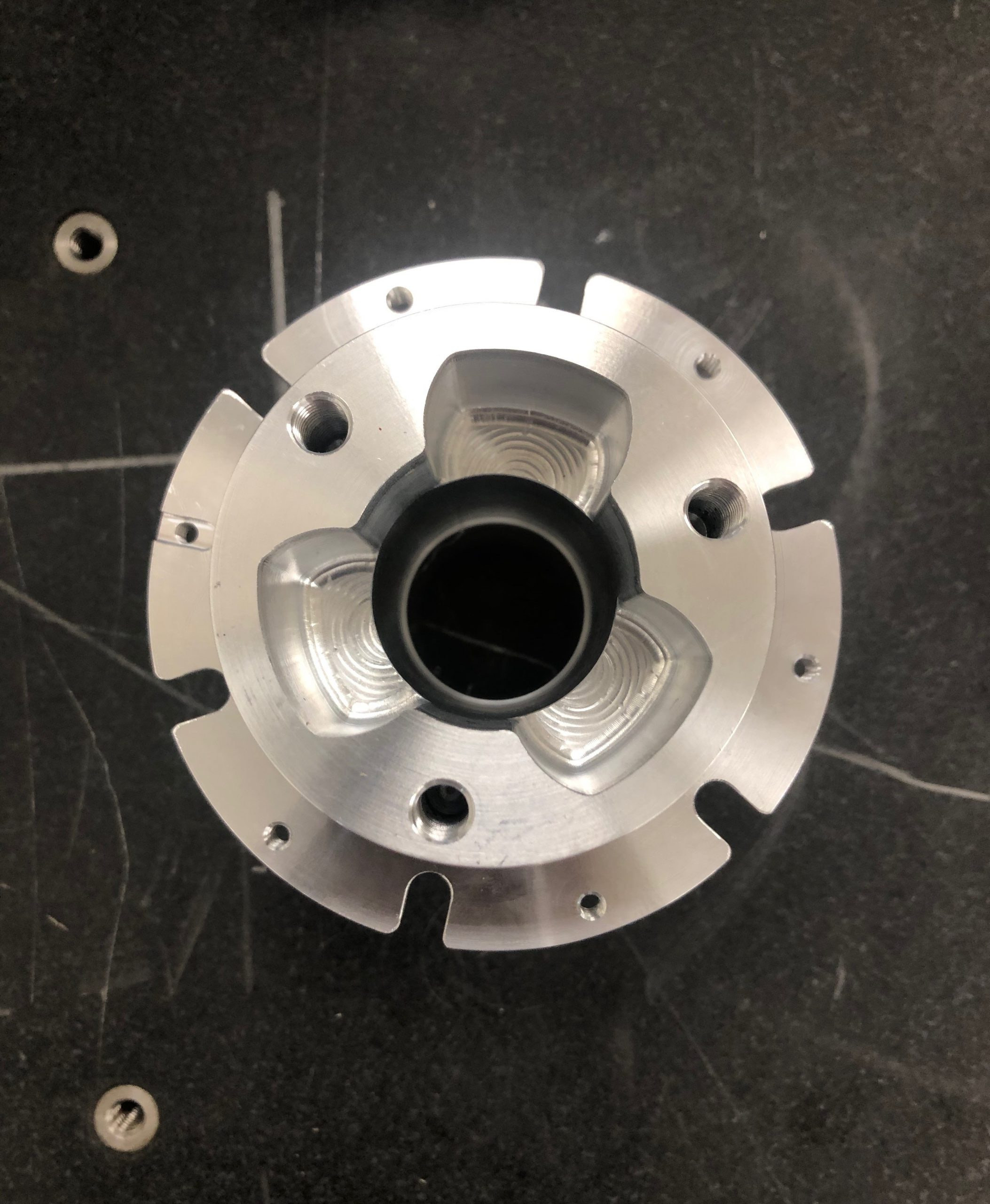

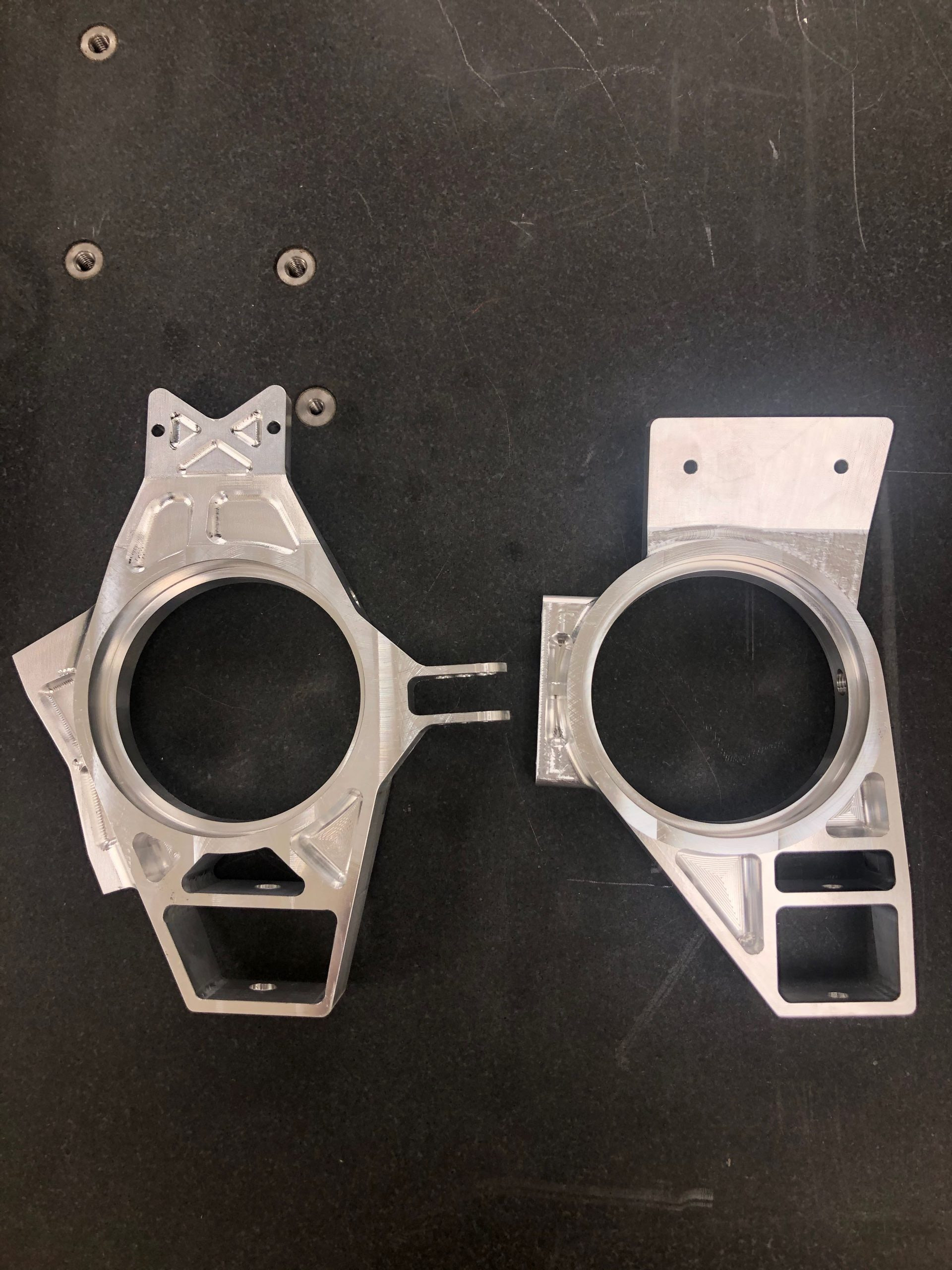

Expertly crafted aluminum component by PMi2—designed for durability, precision, and versatility in advanced manufacturing applications.

Close-up of freshly machined aluminum part. PMi2 also machines components from high-tech alloys.

Newly machined parts set for display at PMi2.

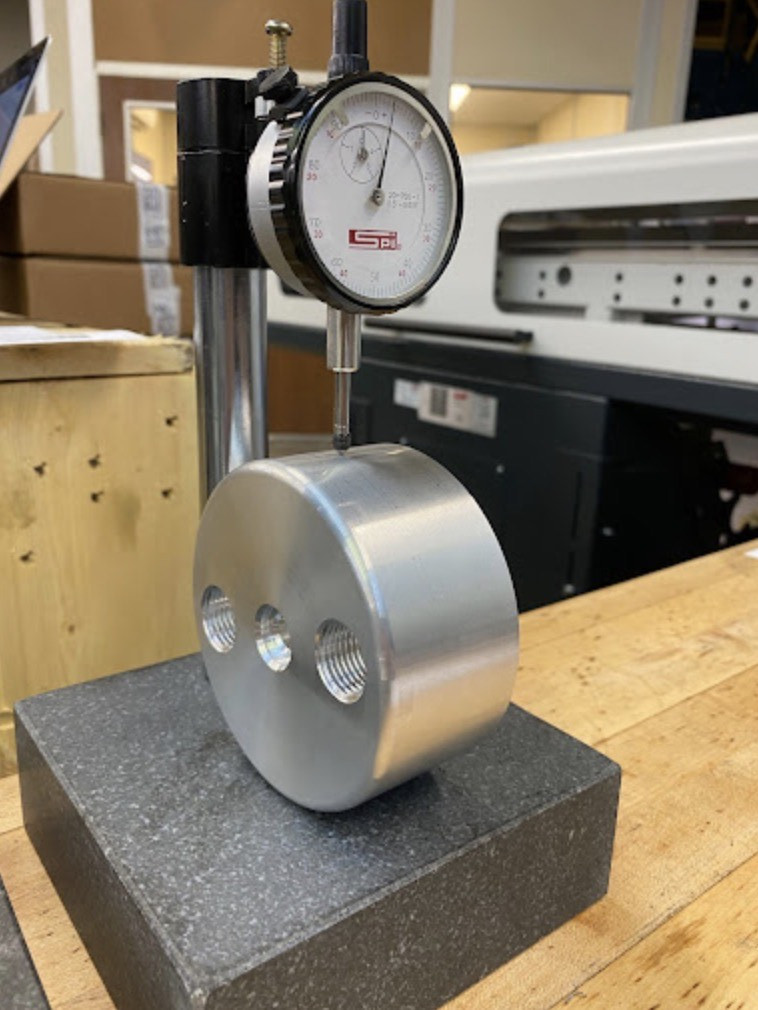

PMi2 utilizes a precision dial indicator mounted on a granite surface plate to ensure the accuracy and quality of machined components. This setup allows for detailed dimensional analysis and tolerance verification, meeting stringent industry standards for high-performance applications.

PMi2 uses Mitutoyo CMMs to ensure precise, reliable components, supporting quality control and prototyping across industries like automotive and aerospace.

PMi2 machines a variety of metals.

PMi2 employs the Hyundai WIA L230LMSA CNC machine for precise, efficient machining, ensuring high-quality results for every project.

PMi2 utilizes Charmilles wire EDM machines for precision cutting, enabling the production of intricate components for industries such as aerospace and automotive.

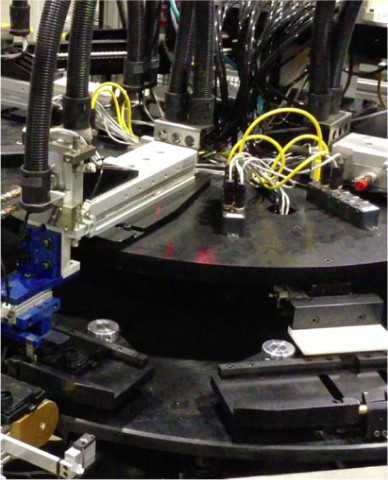

PMi2 showcases its innovative automation systems equipped with PLC (Programmable Logic Controller) technology.

PMi2's industrial controls are the foundation of reliable manufacturing automation.

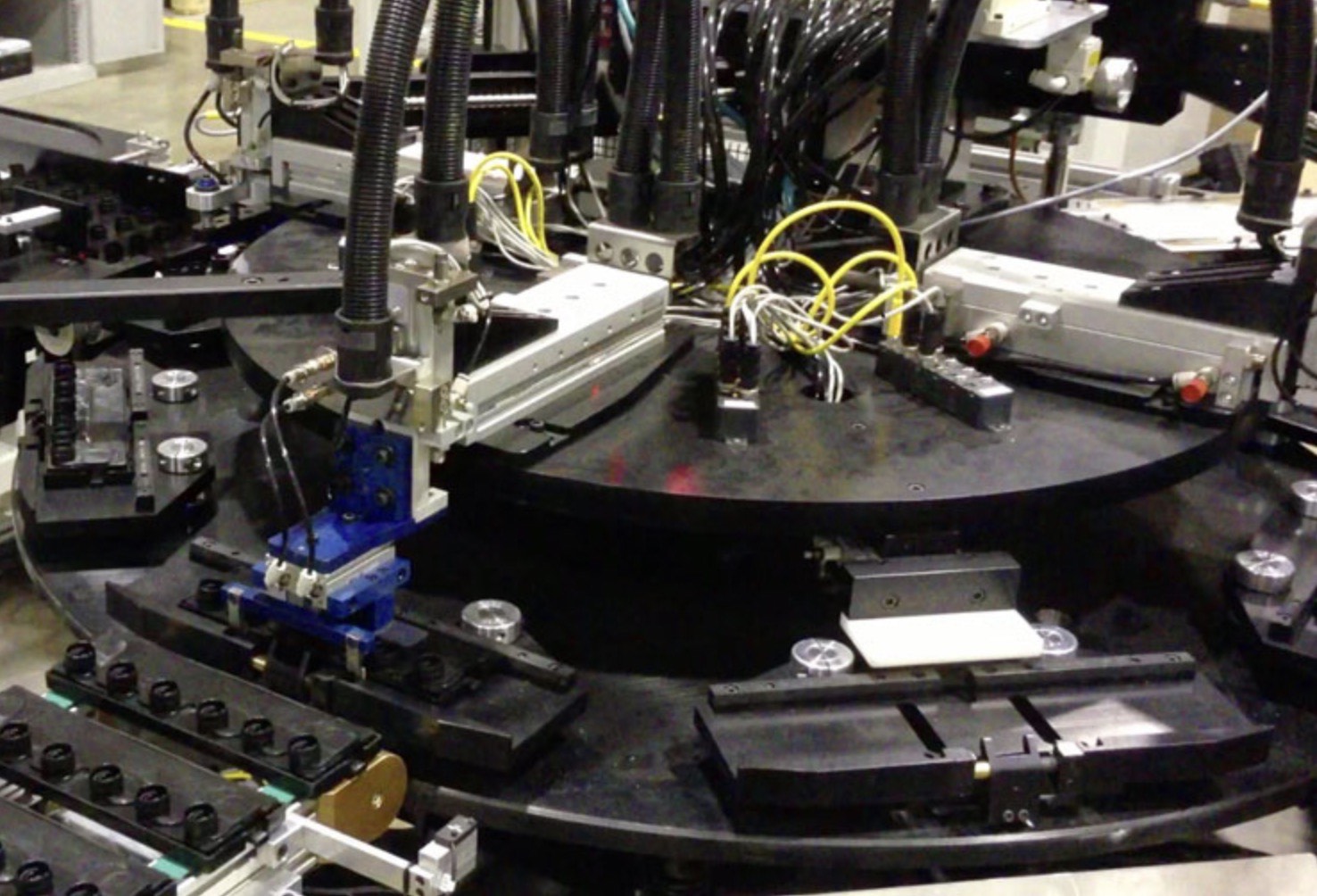

PMi2's rotary indexing table enables accurate component placement and efficient automation, driving reliability in advanced manufacturing processes.

PMi2 delivers precision-machined aluminum components, crafted for durability and performance in mechanical assemblies, ensuring high quality for industrial applications.

PMi2 excels in machining large rolls and shafts with precision and reliability, meeting critical requirements such as durability, dimensional accuracy, and smooth surface finishes. These components are vital for industries requiring high-load capacity, consistent performance, and resistance to wear under demanding conditions.

PMi2 leverages automated picking systems equipped with advanced vision technology to accurately identify and handle parts. This innovation enhances precision, efficiency, and quality in modern manufacturing processes.

PMi2 harnesses advanced automation capabilities with precision-engineered equipment like AM-1450 and AM-1451, driving efficient manufacturing and production workflows.

Contact Us

Working With Us

Learn how we support customers from day one, from machining to automation, design services, and more.

Contact Us